Imishini Yokulinganisa Yokuhlanganisa (ama-CMM) - Izindlu Zamandla Zokulinganisa Ze-3D

Eyaziwa nangokuthi 3 - Imishini Yokulinganisa Ubukhulu (ama-CMM), ama-CMM ethu ayisizinda sohlelo lwethu lokuhlola. Njengoba kuboniswe esithombeni esingezansi, angamadivayisi anembe kakhulu akwazi ukukala ubukhulu bengxenye ngokunemba kweleveli ye-micron.

Ama-CMM athola izinhlelo zokusebenza ezibanzi kuzo zonke izimboni ezihlukahlukene, kusukela ku-aerospace kuye kwezokwelapha. Emkhathini, baqashwe ukuze bahlole izingxenye ezibalulekile ezifana nama-turbine blades, ukuqinisekisa ukuthi ngisho nobukhulu obuncane bungaphakathi kokubekezelela okucacisiwe. Emkhakheni wezokwelapha, baqinisekisa ukunemba kwezinsimbi zokuhlinza nezingxenye zokufakelwa

| Ukucaciswa | Imininingwane |

| Ibanga Lokulinganisa | [X] mm (Ubude) x [Y] mm (Ububanzi) x [Z] mm (Ubude), buvumelana nezinga losayizi abahlukahlukene |

| Ukunemba | Kufika ku-±0.001 mm, ihlinzeka ngezilinganiso ezinembe kakhulu |

| Izinhlobo ze-Probe | Ifakwe i-touch - trigger probe yezilinganiso ezijwayelekile kanye nama-skena ama-probe ukuze uthole iphrofayela eyinkimbinkimbi yendawo |

| I-Software Compatibility | Ihlanganisa nesoftware ye-metrology ehamba phambili yemboni yokuhlaziya idatha nokubika |

Imishini Yokulinganisa Yokuhlanganisa (ama-CMM) - Izindlu Zamandla Zokulinganisa Ze-3D

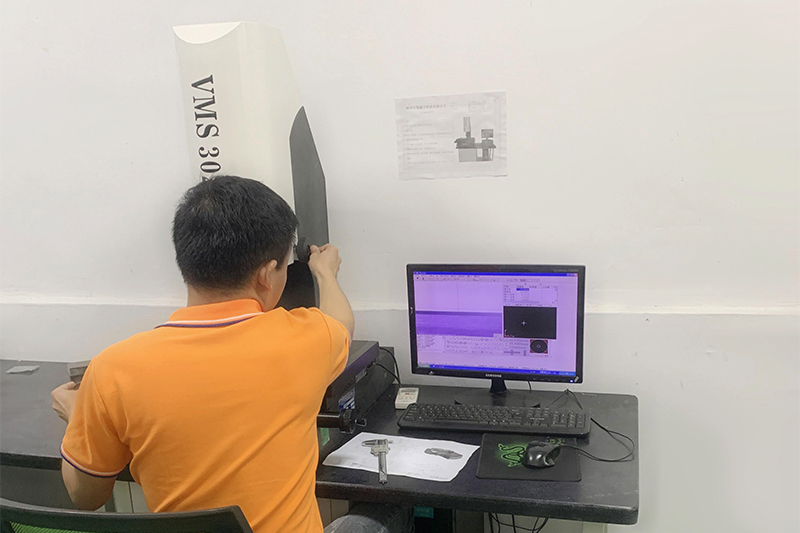

Iziqhathanisi ze-Optical zibalulekile ekuhlolweni okungathintana naye kwezingxenye. Isithombe sibonisa isimiso sokusebenza sesiqhathanisi sokubonwayo, lapho ingxenye ikhuliswa futhi iboniswe esikrinini ukuze ikalwe.

Lezi ziwusizo ikakhulukazi embonini ye-electronics, lapho izingxenye ezincane neziyinkimbinkimbi zidinga ukuhlolwa. Isibonelo, angasetshenziswa ukukala ubukhulu bezixhumi ezincane noma ukuqondanisa kwamathrekhi ebhodi lesifunda. Embonini yamathuluzi - kanye - ne-die, izifanisi ezibonakalayo zisetshenziselwa ukuhlola ukunemba kwesikhunta futhi ziyafa.

| Ukucaciswa | Imininingwane |

| Ibanga Lokukhulisa | Kusukela [Ukukhulisa okuncane]x ukuya ku-[Ubukhulu obukhulu]x, okungalungiseka kumasayizi ahlukene wezingxenye nezimfuneko zokuhlolwa |

| Ukulungiswa Kwesithombe | Imifanekiso enesinqumo esiphezulu, evumela ukubonwa okucacile kwemininingwane emihle |

| Ukunemba Kokulinganisa | ±0.005 mm ngezilinganiso zomugqa, ukuqinisekisa imiphumela ethembekile |

| I-Illumination System | Izici eziguquguqukayo - ukuqina kanye nokukhanya kwama-engeli amaningi ukuthuthukisa ukubonakala kwengxenye |

Ama-Digital Height Gauges - Izilinganiso Eziqondile Eziqondile (I-2.5D Projector).

Amageji obude bedijithali, avame ukubizwa ngokuthi 2.5 - Amathuluzi Okulinganisa Ane-Dimensional, adlala indima ebalulekile enqubweni yethu yokuhlola. Isithombe esingezansi sibonisa igeji yobude bedijithali esetshenziswayo, ikala ubude bocezu lokusebenza ngokunemba.

Lawa ma-gauge asetshenziswa kakhulu kuzilungiselelo zokukhiqiza ukukala ubude, ukujula, kanye nesinyathelo - ubude bezingxenye. Zibaluleke kakhulu ekukhiqizweni kwezingxenye ezisebenza ngomshini ezinembayo, njengalezo ezitholakala ezimbonini zezimoto nezama-semiconductor.

| Ukucaciswa | Imininingwane |

| Ibanga Lokulinganisa | [Ubude obuncane] - [Ubude obukhulu] mm, bufanele ububanzi bengxenye yobude |

| Ukunemba | ±0.01 mm, ihlinzeka ngezilinganiso eziqondile ezithembekile |

| Uhlobo lokubonisa | Isibonisi sedijithali sokufunda kalula nokuqoshwa kwedatha |

| Izinketho ze-Probe | Itholakala ngamathiphu ahlukene we-probe wezinhlobo ezahlukene ze-surface |

Izivivinyo Zokuqina

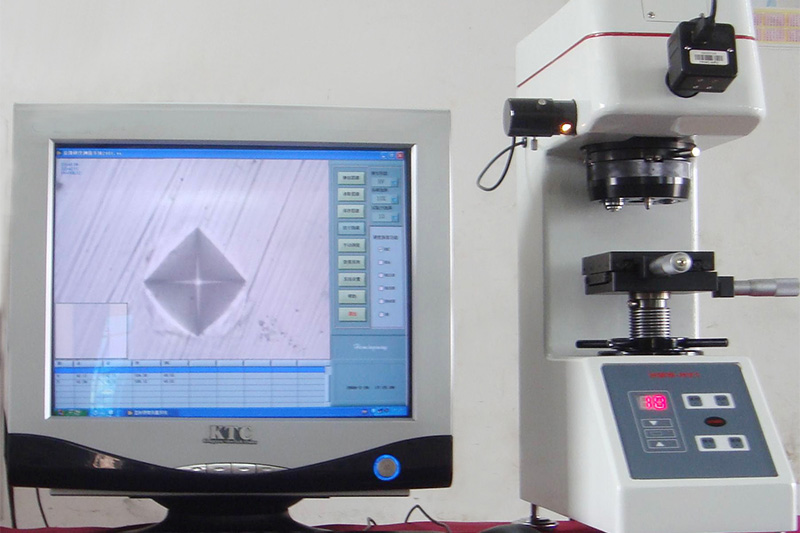

Ukuhlolwa kokuqina kubalulekile ukuze kuqinisekiswe ikhwalithi yezinto ezisetshenziswa ezinqubweni zethu zomshini. Isithombe esingezansi sibonisa umhloli wokuqina osetshenziswa ukukala ubulukhuni besampula yensimbi

Embonini yensimbi, ukuhlola ubulukhuni kusiza ekuqinisekiseni ikhwalithi yezinto ezingavuthiwe nezingxenye eziqediwe. Isibonelo, ekukhiqizeni amagiya, ukuhlolwa kokuqina kuqinisekisa ukuthi impahla ingakwazi ukumelana nemithwalo ephezulu kanye nokucindezeleka ngesikhathi sokusebenza. Sisebenzisa izinhlobo ezahlukene zabahloli bokuqina, okuhlanganisa i-Rockwell, i-Brinell, ne-Vickers, ukuze kuhlangatshezwane nezinto ezihlukahlukene nezimfuneko zokuhlola.

| Ukucaciswa | Imininingwane |

| Ukufakwa Kwesikali Sokuqina | I-Rockwell: A, B, C isikali; I-Brinell: Isikali se-HBW; I-Vickers: Isikali se-HV |

| Testing Force Range | Amandla okuhlola alungisekayo ukuze avumelane namazinga ahlukene wokuqina kwempahla |

| Izinhlobo ze-Interer | Ifakwe ama-identers afanelekile esikalini sobunzima ngasinye |

| Ukunemba | Izilinganiso zokunemba okuphezulu, ngaphakathi kwamayunithi wokuqina ±[X] kuye ngesilinganiso |

Abahloli Bokuqina Kobuso

Ubulukhuni bobuso buyinto ebaluleke kakhulu ezinhlelweni eziningi zokusebenza, futhi abahloli bethu bokuqina kwendawo baklanyelwe ukukala le pharamitha ngokunembile. Isithombe sibonisa isihloli sokuqina komhlaba esisetshenziswayo, siskena indawo engaphezulu yengxenye eyenziwe ngomshini

Ezimbonini ezifana nezezimoto nezokukhiqiza, ubulukhuni bendawo bungaba nomthelela ekusebenzeni nokuqina kwezingxenye. Isibonelo, ezingxenyeni zenjini, ukuphela kwendawo efanele kunganciphisa ukungqubuzana futhi kuthuthukise ukusebenza kahle. Abahloli bethu bobuqhwaga bangakwazi ukukala amapharamitha ahlukene okurhabazeka, afana no-Ra (ukuchezuka kwesilinganiso sezibalo sephrofayela ehloliwe) kanye ne-Rz (isilinganiso sobude seziqongo eziphakeme ezinhlanu nezigodi ezinhlanu ezijulile ngaphakathi kobude bokuhlola).

| Ukucaciswa | Imininingwane |

| Ibanga Lokulinganisa | I-Ra: [inani lika-Min Ra] - [inani elingu-Max Ra] µm, lilungele ukuqedwa okubanzi okungaphezulu |

| Uhlobo lwenzwa | Izinzwa ze-stylus ezinembayo eziphezulu zokwenza iphrofayela enembile yendawo |

| Ubude besampula | Ubude besampula obulungisekayo ukuze buhlangabezane namazinga ahlukene embonini |

| Okukhiphayo kwedatha | Ingakhipha idatha ngamafomethi ahlukahlukene ukuze ihlanganiswe kalula namasistimu okulawula ikhwalithi |

Izibonakhulu

Izibonakhulu zibalulekile ekuhloleni imininingwane emincane ebusweni bezingxenye. Isithombe esingezansi sibonisa isibonakhulu sisetshenziswa ukuhlola ingxenye ekukhuliseni okuphezulu

Ezimbonini ze-elekthronikhi nezobucwebe, ama-microscopes asetshenziselwa ukuhlola ikhwalithi yamalunga ahlanganisiwe, ukuqedwa okungaphezulu kwezinsimbi eziyigugu, nobuqotho bezingxenye ezincane. Zenza ithimba lethu labahloli likwazi ukubona amaphutha nokungapheleli okungabonakali ngeso lenyama.

| Ukucaciswa | Imininingwane |

| Ibanga Lokukhulisa | Kusuka kokuthi [Ukukhulisa okuncane]x ukuya ku-[Ubukhulu obukhulu]x, okuvumela ukuhlolwa okuningiliziwe kumazinga ahlukene— |

| I-Illumination System | Ifakwe ukukhanya kwe-LED okukhanyayo kokubonakala okucacile kwesifanekiso |

| Ikhono lokuthwebula isithombe | Amanye amamodeli asekela ukuthwebula izithombe ukuze kubhalwe futhi kuhlaziywe |

| Ukulungiswa Kwe-Focus | Ukulungiswa okunembile kokugxila kwesithombe esibukhali ekujuleni okuhlukahlukene |

Ama-Micrometers

Ama-Micrometer anembile - amathuluzi okulinganisa asetshenziselwa ukuthatha izilinganiso zomugqa ezinembe kakhulu. Isithombe esingezansi sibonisa i-micrometer esetshenziswa ukukala ububanzi bengxenye yesilinda

Zivame ukusetshenziswa emisebenzini yomshini ukukala ububanzi be-shafts, ukushuba kwezinto, kanye nokujula kwezimbobo. Ama-Micrometer aziwa ngokunemba kwawo okuphezulu futhi ayithuluzi elibalulekile kunoma iyiphi indawo yokukhiqiza enembayo

| Ukucaciswa | Imininingwane |

| Ibanga Lokulinganisa | [Isilinganiso esincane] - [Isilinganiso esiphezulu] mm, sitholakala kububanzi obuhlukene bezinhlelo zokusebenza ezihlukahlukene |

| Ukunemba | ±0.001 mm, ihlinzeka ngezilinganiso zomugqa ezinembe kakhulu |

| I-Anvil and Spindle Design | Precision - ama-anvils aphansi kanye nama-spindles okulinganisa okungaguquki nokuthembekile |

| I-Locking Mechanism | Ifakwe umshini wokukhiya ukuze ibambe isikali endaweni |

Ama-Calipers

Ama-Caliper angamathuluzi okulinganisa ahlukahlukene angasetshenziswa ukukala ubukhulu bangaphakathi, bangaphandle, nokujula kwezingxenye. Isithombe esingezansi sibonisa i-digital caliper esetshenziswa ukukala ububanzi bengxenye.

Zisetshenziswa kakhulu ezimbonini ezihlukahlukene, kusukela ekwenzeni ukhuni kuya ekwenzeni insimbi. Ama-Calipers anikeza indlela elula nenembile yokuthatha izilinganiso ezisheshayo phakathi nenqubo yokukhiqiza.

| Ukucaciswa | Imininingwane |

| Ibanga Lokukhulisa | Kusuka kokuthi [Ukukhulisa okuncane]x ukuya ku-[Ubukhulu obukhulu]x, okuvumela ukuhlolwa okuningiliziwe kumazinga ahlukene— |

| I-Illumination System | Ifakwe ukukhanya kwe-LED okukhanyayo kokubonakala okucacile kwesifanekiso |

| Ikhono lokuthwebula isithombe | Amanye amamodeli asekela ukuthwebula izithombe ukuze kubhalwe futhi kuhlaziywe |

| Ukulungiswa Kwe-Focus | Ukulungiswa okunembile kokugxila kwesithombe esibukhali ekujuleni okuhlukahlukene |

Ama-plug Gauges

Ama-plug gauge asetshenziselwa ukuhlola ububanzi bangaphakathi bezimbobo nezimbobo. Isithombe esingezansi sibonisa isethi yamageji epulaki asetshenziselwa ukuhlola imbobo kucezu lokusebenza

Ekwenziweni kwezingxenye ezinjengamasilinda enjini, amavalvu, namapayipi, ama-plug gauge aqinisekisa ukuthi ama-diameter angaphakathi ahlangabezana nokubekezelelana okucacisiwe. Angamathuluzi alula kodwa asebenza kahle kakhulu okulawula ikhwalithi ezilinganisweni ezihlobene nezimbobo

| Ukucaciswa | Imininingwane |

| I-Gauge Diameter Range | [Ubukhulu obuncane] - [Ubukhulu obukhulu] mm, etholakala ngosayizi abahlukahlukene ukuze ifane namadayamitha embobo ahlukene |

| Ikilasi Lokubekezelelana | Yenzelwe amakilasi athile okubekezelelana, njenge-H7, H8, njll., ukuze kuqinisekiswe ukufaneleka okunembile |

| Okubalulekile | Yenziwe ngensimbi eqinile yekhwalithi ephezulu ukuze iqine futhi imelane nokugqoka |

| I-Surface Finish | Ukuqedwa kwengaphezulu okubushelelezi ukuvimbela ukulimala engxenyeni ehlolwayo |