Isingeniso

Emhlabeni osheshayo wamakhompiyutha nezinto zikagesi ezithengwayo, isidingo sezingxenye zomshini ezinembayo, ezinokwethenjelwa, kanye nentsha sikhula njalo. Imikhiqizo yethu eyenziwe ngomshini idizayinelwe futhi yakhiwe ukuze ihlangabezane nezidingo ezithile zale mboni eguquguqukayo, idlala indima ebalulekile ekuthuthukiseni ukusebenza, ukusebenza, kanye nobuhle bemishini ehlukahlukene kagesi.

Izingxenye Zomshini Ezibalulekile Nezicelo Zazo

Amasinki okushisa kanye nezixazululo zokupholisa

■ Umsebenzi:Ngamandla akhulayo nokusebenza kwama-computer processors kanye nezingxenye ze-electronic, ukuchithwa kokushisa okusebenzayo kubalulekile. Amasinki okushisa akhiwe ngomshini aklanyelwe ukudonsa ukushisa kude nalezi zingxenye futhi akukhiphe emoyeni ozungezile. Idizayini enembile kanye nomshini wamaphiko namashaneli kuqinisekisa indawo ephezulu yokudlulisa ukushisa, nokubekezelela okuqinile njengokungu-±0.05mm kuya ku-±0.1mm. Lokhu kusiza ukugcina izinga lokushisa elilungile lokusebenza kwedivayisi, ukuvimbela ukushisa ngokweqile kanye nokulimala okungenzeka.

■ Ukukhetha Okubalulekile:Ama-alloys e-aluminium avame ukusetshenziswa ngenxa ye-thermal conductivity enhle kakhulu kanye nemvelo engasindi. Isibonelo, i-aluminium 6061 ne-6063 yizinketho ezidumile. Kwezinye izimo, ithusi lingase futhi isetshenziselwe conductivity yayo ephakeme nakakhulu ezishisayo, ikakhulukazi izicelo amandla aphezulu. Ukwelapha okungaphezulu okufana ne-anodizing kungasetshenziswa ukuze kuthuthukiswe ukunqanyulwa kokushisa nokuvikela ekugqwaleni.

Chassis kanye Ezivalekile

■ Umsebenzi:I-chassis nezivalo azihlinzeki ngokuvikeleka ngokomzimba kuphela kwezingxenye ze-elekthronikhi zangaphakathi kodwa futhi zifaka isandla ekwakhiweni kukonke kanye ne-ergonomics yedivayisi. Kudingeka zenziwe ngomshini ngokunembile ukuze kuqinisekiswe ukulingana okufanele nokuhlangana kwazo zonke izingxenye, nokubekezelelana ngokuvamile phakathi kuka-±0.1mm kuya ku-±0.3mm. Ukukhethwa kwempahla nokuqedwa kuthinta ukuqina kwedivayisi, ubuhle, kanye namandla kazibuthe e-electromagnetic interference (EMI) okuvikela.

■ Ukucatshangelwa kwezinto:Kusetshenziswa izinto ezifana nama-alloys e-aluminium, insimbi engagqwali, namapulasitiki obunjiniyela. I-Aluminiyamu inikeza ibhalansi enhle yamandla, isisindo, kanye nokusebenza kanzima. Insimbi engagqwali inikeza ukuqina okuthuthukisiwe kanye nokuvikela kwe-EMI. Amapulasitiki obunjiniyela, afana ne-ABS (Acrylonitrile Butadiene Styrene) ne-PC (Polycarbonate), athandwa kakhulu ngezindleko zawo eziphansi, ukuguquguquka kokuklama, kanye nezakhiwo zokushisa.

Izixhumi Ezinembile kanye Nobakaki Okhwezayo

■Umsebenzi:Izixhumi nabakaki abakhwezayo kubalulekile ekusebenzeni kahle nokuhlanganisa izingxenye ze-elekthronikhi. Ukunemba kwemishini kuqinisekisa ukuqondanisa okunembile nokuxhumana okuvikelekile phakathi kwezingxenye ezihlukene, njengamabhodi wesifunda, ama-hard drive, namaphaneli esibonisi. Ukubekezelela izixhumi kungaba kuhle njengo-±0.02mm ukuya ku-±0.05mm ukuze kuqinisekiswe ukuxhunywa okuthembekile kukagesi nokomshini. Abakaki abakhwezwayo badinga ukwakhiwa ngokunembile ukuze kubambe izingxenye endaweni ziqine.

■ Impahla kanye Nemishini:I-Brass nensimbi engagqwali kuvame ukusetshenziselwa izixhumi ngenxa ye-conductivity enhle nokumelana nokugqwala. Kubakaki abakhwezwayo, ama-alloys e-aluminium noma insimbi ingasetshenziswa kuye ngezidingo zamandla. Amasu okumaka athuthukile afana ne-micro-milling kanye ne-EDM yocingo (Electrical Discharge Machining) ngokuvamile asetshenziswa ukuze kuzuzwe ukunemba okudingekayo kanye nokwakheka okuyinkimbinkimbi.

Ukuqinisekiswa Kwekhwalithi kanye Nezinqubo Zomshini Wokunemba

Ukuqinisekisa ikhwalithi

■Senze isistimu yokulawula ikhwalithi eqinile ukuze siqinisekise ikhwalithi ephezulu kakhulu yemikhiqizo yethu eyenziwe ngomshini yekhompuyutha kanye nemboni yezogesi zabathengi. Lokhu kubandakanya ukuhlolwa okuphelele kwezinto ezingenayo ukuze kuqinisekiswe ikhwalithi nokucaciswa kwezinto ezingavuthiwe. Ngesikhathi senqubo yokwenza imishini, ukuhlolwa okungaphakathi kwenqubo kwenziwa ezigabeni eziningi kusetshenziswa imishini ye-metrology ethuthukisiwe njengemishini yokulinganisa yokuxhumanisa (ama-CMM), ama-profilometer okubona, kanye namadivayisi okuhlola kagesi. Imikhiqizo yokugcina ihlolwa ikhwalithi ebanzi, okuhlanganisa ukuqinisekiswa kokunemba kobukhulu, ukuhlolwa kokusebenza, nokuhlolwa kwezimonyo, ukuze kuhlangatshezwane namazinga aqinile emakethe kagesi.

■ Ukwengeza, senza izivivinyo zemvelo kanye nokuthembeka okufana nokuhamba ngebhayisikili lokushisa nomswakama, ukuhlola ukushaqeka nokudlidliza, ukuze siqinisekise ukuthi imikhiqizo yethu ingakwazi ukumelana nezimo zokusebenza ezinzima namaphethini okusetshenziswa kwezinto zikagesi.

Precision Machining Izinqubo

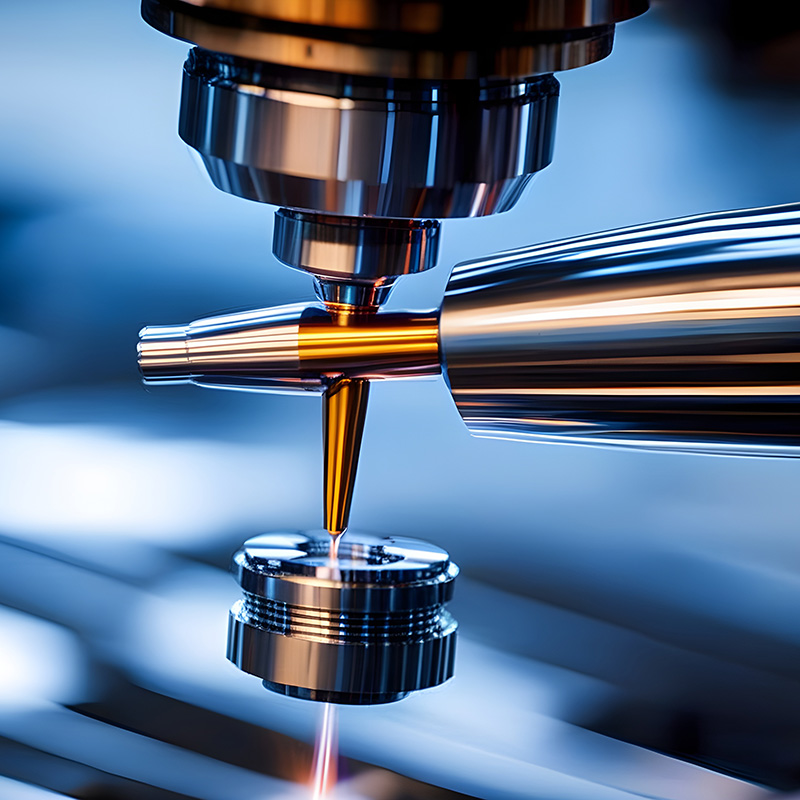

■ Imisebenzi yethu yokwenza imishini isebenzisa imishini yesimanjemanje ye-CNC (Computer Numerical Control) efakwe ama-spindle anembe kakhulu kanye nezinhlelo zamathuluzi ezithuthukisiwe. Sisebenzisa amasu okwenza imishini ahlukahlukene, afaka ukugaya okunesivinini esikhulu, ukujika, ukugaya, nokubhola ukunemba, ukuze sifinyelele ukubekezelela okuqinile namajiyometri ayinkimbinkimbi adingekayo ezingxenyeni ze-elekthronikhi.

■ Omashini bethu abanolwazi nonjiniyela basebenzisana eduze nabakhiqizi bezinto zikagesi ukuze bathuthukise izinqubo zokumaka ngokusekelwe kumklamo othize kanye nezidingo zokusebenza zomkhiqizo ngamunye. Lokhu kuhilela ukuthuthukisa amathuluzi angokwezifiso kanye nezinhlelo zokuqinisekisa ukukhiqizwa okuphumelelayo nokunembile.

Ukwenza ngokwezifiso Nokwesekwa Komklamo

Ukwenza ngokwezifiso

■ Siyaqonda ukuthi imboni yamakhompiyutha kanye nemishini kagesi yabathengi inokuncintisana kakhulu futhi ilokhu ivela njalo, lapho abakhiqizi befuna izingxenye ezihlukile futhi ezenziwe ngokwezifiso ukuze bahlukanise imikhiqizo yabo. Ngakho-ke, sinikeza izinketho eziningi zokwenza ngokwezifiso zemikhiqizo yethu eyenziwe ngomshini. Kungakhathaliseki ukuthi isizinda sokushisa esiklanywe ngokwezifiso sesizukulwane esisha samaphrosesa, indawo evalekile ekhethekile enento ehlukile yefomu, noma isixhumi esinembayo esinokucushwa kwephinikhodi okungajwayelekile, singasebenza nawe ukuze sithuthukise futhi sikhiqize isisombululo esihle kakhulu.

■ Ithimba lethu lokuklama nobunjiniyela liyatholakala ukuze lisebenzisane nezinkampani ze-elekthronikhi kusukela esigabeni sokuqala somqondo kuya ekukhiqizweni kokugcina, linikeza okokufaka okubalulekile nobungcweti bokuqinisekisa ukuhlanganiswa okungenazihibe kwezingxenye eziwumshini ekwakhiweni kwedivayisi iyonke.

Ukusekela Kwedizayini

■Ngokungeziwe ekwenzeni ngendlela oyifisayo, sinikezela ngezinsizakalo zosekelo lwedizayini ukusiza abakhiqizi bezinto zikagesi bathuthukise ukusebenza nokwenziwa kwemikhiqizo yabo. Ithimba lethu lochwepheshe lingasiza ekukhetheni impahla, ukuhlaziya ukwakheka kwe-manufacturability (DFM), kanye ne-prototyping. Sisebenzisa isofthiwe ethuthukisiwe ye-CAD/CAM (I-Computer-Aided Design/Computer-Aided Manufacturing), singalingisa inqubo yokwenza imishini futhi sihlonze izinkinga ezingaba khona zokuklama ngaphambi kokukhiqiza, sehlise isikhathi sokuthuthukiswa nezindleko kuyilapho sithuthukisa ikhwalithi nokwethembeka komkhiqizo wokugcina.

Isiphetho

UMKOPI

Imikhiqizo yethu eyenziwe ngomshini inikezela ngokunemba, ikhwalithi, kanye nokwenza ngokwezifiso okudingekayo embonini yamakhompiyutha kanye nabathengi. Ngezinhlobonhlobo zezinto zokwakha kanye nekhono lomshini, siyakwazi ukuhlinzeka ngezixazululo ezinokwethenjelwa zezinhlelo zokusebenza ezihlukahlukene, kusukela ekulahlekeni kokushisa nokwakhiwa kwe-chassis kuya kwezixhumi nakubakaki abakhulayo. Noma ngabe udinga i-prototype eyodwa noma ukukhiqizwa kwenani elikhulu, sizibophezele ekuletheni izingxenye zomshini zekhwalithi ephezulu ezihlangabezana futhi zidlule okulindelwe yimakethe ye-electronics.

Xhumana nathi namuhla ukuze uxoxe ngekhompyutha yakho kanye nezidingo zemishini kagesi ezithengwayo futhi sikuvumele sikusize uphilise imibono yakho emisha.

Isikhathi sokuthumela: Feb-15-2025