Isingeniso

Emhlabeni wokuthatha izithombe, ikhwalithi nokusebenza kwemishini kuncike kakhulu ezingxenyeni ezifakwe ngomshini. Imikhiqizo yethu eyenziwe ngomshini yakhiwe ngobunono ukuze ihlangabezane nezidingo eziqondile zemboni yezithombe, ithuthukisa ukusebenza, ukuqina, kanye nokunemba kwemishini ehlukahlukene yezithombe.

Izingxenye Zomshini Ezibalulekile Nezicelo Zazo

Izingxenye Zomzimba Wekhamera

■ Umsebenzi:Umzimba wekhamera uwumgogodla wazo zonke izisetshenziswa zezithombe. Izingxenye ezakhiwe ngomshini ezifana ne-chassis yekhamera, ukukhwezwa kwelensi, kanye nezindlu zemishini yokuvala zibalulekile ekusebenzeni kwayo okufanele. I-chassis inikeza isakhiwo esizinzile nesiqinile, esiqinisekisa ukuthi zonke izingxenye zangaphakathi ziqondaniswe ngokunembile. Ukukhwezwa kwelensi, nokubekezelela ngokuvamile phakathi kuka-±0.02mm kuya ku-±0.05mm, kufanele kwenziwe ngomshini ngokunemba okuphezulu kakhulu ukuze kuqinisekiswe ukulingana okuphelele nokuxhumana okungenazihibe phakathi kwekhamera nelensi, kuvinjwe noma yikuphi ukuvuza kokukhanya noma ukungahambi kahle okungase kuthinte ikhwalithi yesithombe. I-shutter mechanism yezindlu ivikela izingxenye ze-shutter ezintekenteke futhi inomthelela ekusebenzeni kahle nokunembile kwesivalo, okubalulekile ekuthwebuleni izithombe ezibukhali.

■ Ukukhetha Okubalulekile:Izinto ezifana nama-alloys e-aluminium nama-magnesium alloys zivame ukusetshenziselwa imizimba yekhamera. Ama-alloys e-aluminium anikeza ibhalansi enhle yamandla, isisindo, kanye nezindleko, kuyilapho ingxube ye-magnesium ilula nakakhulu futhi inikeza izici ezinhle kakhulu zokudambisa, inciphisa ukudlidliza okungafiphalisa izithombe. Ngokufakwa kwelensi, insimbi engagqwali ivame ukuthandwa ngenxa yamandla ayo aphezulu kanye nokumelana nokugqoka.

Izingxenye Zelensi

■ Umsebenzi:Amalensi angamehlo ekhamera, futhi ukunemba kwawo kubaluleke kakhulu. Imiphongolo yelensi eyenziwe ngomshini, izindandatho zokugxila, nezinsimbi zokuvula ziyizingxenye ezibalulekile. Umphongolo welensi udinga ukwenziwa ngomshini ngokubekezelelana okuqinile, ngokuvamile phakathi kuka-±0.05mm kuya ku-±0.1mm, ukuze kuqinisekiswe ukuhleleka okufanele kwezakhi zamalensi kanye nokuhlinzeka ngokusondeza okunembayo nokunemba kanye nokusebenza okugxilile. Iringi yokugxilisa kanye nezinsimbi zokuvula zidinga ukukhanda okunembayo ukuze kuvunyelwe ukulungiswa okunembile nokushelelayo, okuvumela abathwebuli bezithombe ukuthi balawule ukujula kwenkambu futhi bagxile ngokunembile ezihlokweni zabo.

■ Ukucatshangelwa kwezinto:Emiphongolweni yelensi, kusetshenziswa izinto ezifana nama-alloys e-aluminium nethusi. Ama-alloys e-aluminium alula futhi angenziwa nge-anodized ukuze aqine futhi abambe kangcono. I-Brass inikeza ukusebenza okuhle kakhulu nokuzinza, okuzuzisa izingxenye ze-optical ezinembayo. Izakhi zamalensi ngokwazo zenziwa ngezingilazi zamehlo ezihlukahlukene, ezigayiwe futhi ziphucuziwe ukuze zikwazi ukubekezelela kahle kakhulu ukuze kuzuzwe ukusebenza okufiswayo kokubona.

Ukuqinisekiswa Kwekhwalithi kanye Nezinqubo Zomshini Wokunemba

Ukuqinisekisa ikhwalithi

■ Senze uhlelo olubanzi lokulawula ikhwalithi ukuze siqinisekise ikhwalithi ephezulu kakhulu yemikhiqizo yethu eyenziwe ngomshini yemishini yokuthwebula izithombe. Lokhu kubandakanya ukuhlolwa okuqinile kwempahla engenayo ukuze kuqinisekiswe ikhwalithi nokucaciswa kwezinto ezingavuthiwe. Phakathi nenqubo yokwenza imishini, ukuhlolwa okungaphakathi kwenqubo kwenziwa ngezikhathi ezithile kusetshenziswa imishini ye-metrology ethuthukisiwe njengemishini yokulinganisa yokuxhumanisa (ama-CMM), ama-profilometer okubona, nama-interferometer. Imikhiqizo yokugcina ihlolwa ikhwalithi eqinile, okuhlanganisa ukuqinisekiswa kokunemba kobukhulu, ukuhlolwa kokusebenza kokubona, nokuhlolwa kokuqina, ukuze kuhlangatshezwane namazinga aqinile embonini yezithombe.

■ Ukwengeza, senza izivivinyo zemvelo ezifana nokuhamba ngebhayisikili lokushisa nomswakama, ukuhlola ukushaqeka nokudlidliza, ukuze siqinisekise ukuthi imikhiqizo yethu ingamelana nezimo ezinzima abathwebuli bezithombe abangahlangabezana nazo ensimini.

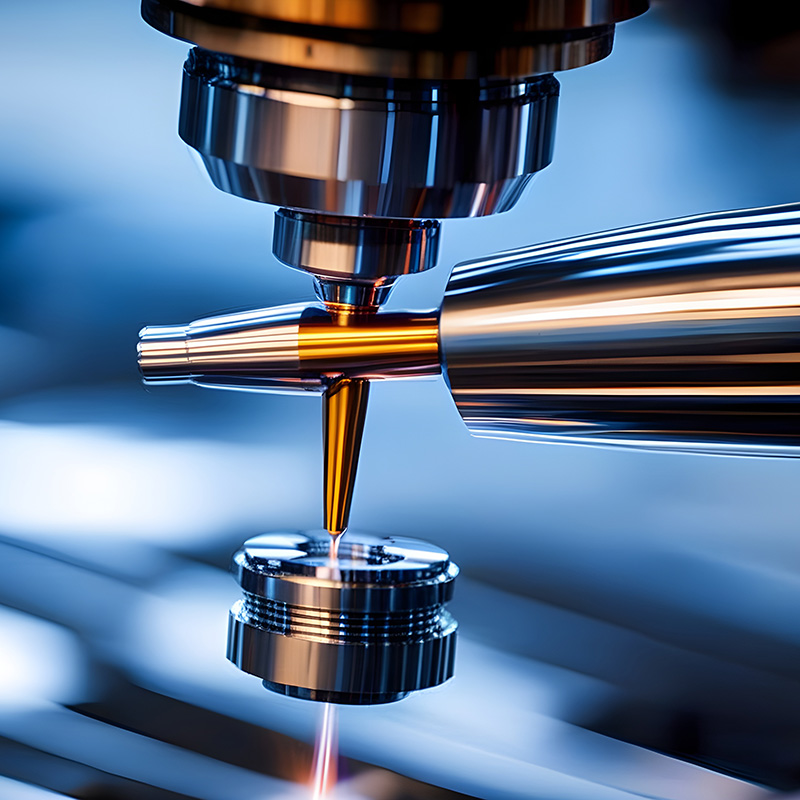

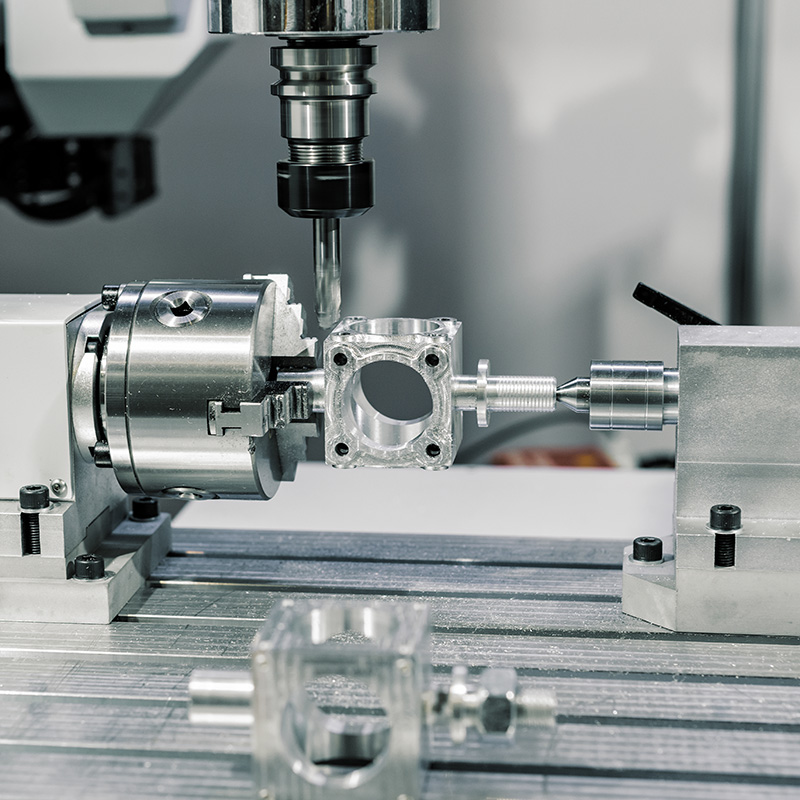

Precision Machining Izinqubo

■ Imisebenzi yethu yokwenza imishini isebenzisa imishini yesimanjemanje ye-CNC (Computer Numerical Control) efakwe ama-spindle anembe kakhulu kanye nezinhlelo zamathuluzi ezithuthukisiwe. Sisebenzisa amasu okwenza imishini ahlukahlukene, okuhlanganisa ukugaya okunesivinini esikhulu, ukuphenduka, ukugaya, nokugqwala, ukuze sifinyelele ukubekezelelana okuqinile namajiyometri ayinkimbinkimbi adingekayo ezingxenyeni zezithombe.

■ Omashini bethu abanolwazi nonjiniyela basebenzisana eduze nabakhiqizi bemishini yokuthwebula izithombe ukuze bathuthukise izinqubo zomshini ngokusekelwe kumklamo othize kanye nezidingo zokusebenza zomkhiqizo ngamunye. Lokhu kuhilela ukuthuthukisa amathuluzi angokwezifiso kanye nezinhlelo zokuqinisekisa ukukhiqizwa okuphumelelayo nokunembile.

Ukwesekwa Kokwenza Ngokwezifiso Nokwakheka

Ukwenza ngokwezifiso

■ Siyaqonda ukuthi abathwebuli bezithombe nabakhiqizi bemishini bavame ukuba nezidingo ezihlukile kanye nemibono yokuqamba. Ngakho-ke, sinikeza izinketho eziningi zokwenza ngokwezifiso zemikhiqizo yethu eyenziwe ngomshini. Kungakhathaliseki ukuthi umzimba wekhamera oklanywe ngokwezifiso wesitayela esithile sokuthatha izithombe noma ilensi ekhethekile enezici ezihlukile zokubona, singasebenza nawe ukuze senze umbono wakho uphile. Singashintsha usayizi, umumo, impahla, kanye nesiphetho sezingxenye zethu zomshini ukuze sihlangabezane nezidingo zakho ngqo.

■ Ithimba lethu lokuklama nobunjiniyela liyatholakala ukuze lisebenzisane nezinkampani zezithombe kusukela esigabeni sokuqala somqondo kuya ekukhiqizweni kokugcina, linikeza okokufaka okubalulekile nolwazi olubalulekile ukuze kuqinisekiswe ukuhlanganiswa okungenazihibe kwezingxenye ezenziwe ngomshini ekwakhiweni kwemishini iyonke.

Ukusekela Kwedizayini

■ Ngaphezu kokwenza ngendlela oyifisayo, sihlinzeka ngamasevisi asekela idizayini ukuze sisize abakhiqizi bezinto zokuthwebula izithombe bathuthukise ukusebenza nokwenziwa kwemikhiqizo yabo. Ithimba lethu lochwepheshe lingasiza ekukhetheni impahla, ukuhlaziya ukwakheka kwe-manufacturability (DFM), kanye ne-prototyping. Sisebenzisa isofthiwe ethuthukisiwe ye-CAD/CAM (I-Computer-Aided Design/Computer-Aided Manufacturing), singalingisa inqubo yokwenza imishini futhi sihlonze izinkinga ezingaba khona zokuklama ngaphambi kokukhiqiza, sehlise isikhathi sokuthuthukiswa nezindleko kuyilapho sithuthukisa ikhwalithi nokwethembeka komkhiqizo wokugcina.

Isiphetho

I-COPYWRITER

Imikhiqizo yethu eyenziwe ngomshini inikeza ukunemba, ikhwalithi, kanye nokwenza ngokwezifiso okudingekayo embonini yemishini yezithombe. Ngezinhlobonhlobo zezinto zokwakha kanye nekhono lomshini, siyakwazi ukunikeza izixazululo ezinokwethenjelwa zezinhlelo zokusebenza ezihlukahlukene, kusukela emizimbeni yekhamera kuya kumalensi. Noma ngabe udinga i-prototype eyodwa noma ukukhiqizwa kwenani elikhulu, sizibophezele ekuletheni izingxenye zomshini zekhwalithi ephezulu ezihlangabezana futhi zidlule okulindelwe yimakethe yezithombe.

Xhumana nathi namuhla ukuze uxoxe ngezidingo zakho zokwenza imishini yezithombe futhi sikuvumele sikusize uthwebule isithombe esihle kakhulu ngezinto zethu eziklanywe ukunemba.

Isikhathi sokuthumela: Feb-15-2025